The Most Hated Man in the Southern States

Chapter 8

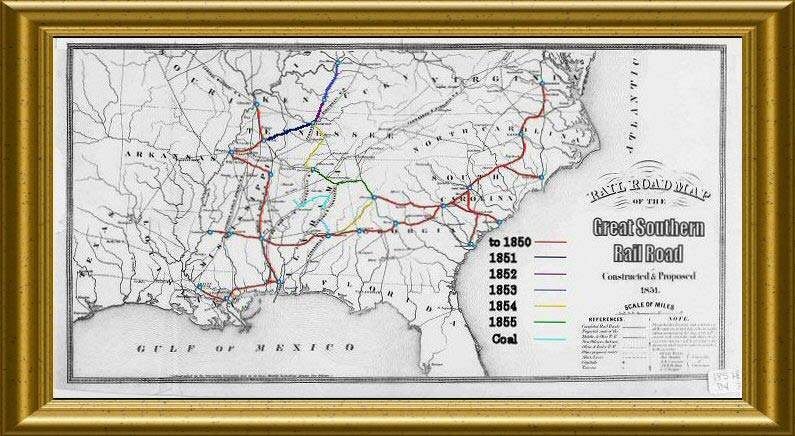

The Great Southern Railroad of 1850 and its Principal Stations

I look back now from my vantage of years and experience and I curse myself as a fool. I thought myself a plain man of business, a railroad man whose task it was to serve the people of the Southern states, bestow upon them the blessings of commerce, and open new lands for settlement, all for a modest fee. I did not then see what should have been plain before my eyes: in the South, there was no separating business and politics. No middle ground remained upon which the disinterested or uncertain might stand; intolerance was to be shown to anyone whose might venture an original opinion.

The political atmosphere was become more noxious with each passing day. Every issue, no matter how minor, was examined for its utility to the Southern cause. If it could be made into a weapon 'gainst the North it was used ruthlessly and without compunction. If the issue could not be so directed, it was anathema! blasphemy! It must be rooted out, burned, no quarter and no mercy! So behaved our great men, our public figures, in those days.

The Presidential election of 1848 had been hotly contested. James Polk the incumbent was passed over by his own party; victory in Mexico and the doubling of American territory paradoxically insured he would be turned out and forgotten. Lewis Cass of Michigan was a good man but not zealous enough in his anti-slavery views; the Free Soil Party drew off enough votes in the Northeast with a stronger anti-slavery program to give the election to Zachary Taylor, general and war hero. Southerners rejoiced; Taylor was a slave-owner and plantation man of Louisiana, after all.

President Taylor promptly recommended that California and New Mexico be admitted as states, knowing their citizens would almost certainly vote to bar slavery. This would decisively tip the balance of power in Congress against the South. Southern congressmen therefore rose up in wrath and resorted to the bluster and bullying that had worked so well in years past, confronting the President with threats of secession and disunion. Like Andrew Jackson before him, Taylor said, he would lead the Federal army into all such states. Persons "taken in rebellion against the Union, he would hang ... with less reluctance than he had hanged deserters and spies in Mexico," Taylor replied. With this sally the hot air was let out and the bullies outfaced. In a few months Taylor died - was poisoned, some say - and former Vice-President Fillmore proved more tractable.

The Compromise of 1850 was both Henry Clay's great achievement and great failure. It did provide a basis for getting past the immediate crisis but achieved no solution of the underlying problems; as wall-paper applied to a crack does nothing to secure the structural soundness of the shifting wall while hiding the severity of the problem, so it was with this great compromise. The South was united in its demand that slavery be allowed to expand indefinitely, if not in the western states then in new territory seized from Central and South America. The rest of the country did not want slavery introduced into new states but rather confined in its existing extent. The rapacity with which cotton devoured the nutrients from the soil made this infeasible; to continue the cotton boom, there must be new land brought into cultivation, and slaves to work that land. Then, too, there was the seemingly intractable problem of what to do with the four millions of slaves currently resident in the South if their services should somehow no longer be required.

More importantly, the Fugitive Slave Act the South had so fiercely demanded became a weapon that turned in the hand to wound the one who wielded it. Under the terms of the act any black person could be accused of being an escaped slave on little or no evidence, with the entire power of the Federal government pledged to drag them South. The passage of the act did a great deal to calm the South, but nothing could have done more to arouse the fury of the North. If any one thing made Civil War inevitable, I believe it was this law, for it awakened the complacent North.

But as I say, the South believed the crisis had passed. Prominent men believed they could return to the bargaining table again and again with fresh demands, insisting on having their way at every turn in confidence the North would always accede. I, who still had many friends and relatives in Rhode Island, Connecticut and Massachusetts, was certain that Southern men had misread the character of the North. They did not see the growing conviction in Northern minds that the South could never be conciliated; they refused to see that Northern hearts were touched by the spectacle of weeping men and women led South in chains held by Federal marshals.

I found myself a stranger in a land I had thought my own. Attempts on my part to discuss the problem were met with scorn, derision and vitriolic rancor, and I believe only my wealth and position with the Rail Road saved me from denunciation or even violence. As it was, I learned to keep my views largely to myself if my family and I were to retain any position in society.

The South saw the Compromise as weakness and indecision that could be exploited for the extension of slavery. The North saw it as an attempt to be fair, an attempt spurned by Southern arrogance and greed. A collision was coming, I was certain, more awful than any collision of locomotives. I began to turn my thoughts to the shape such a confrontation might take, and the resources it must require.

Throughout the early part of the decade we continued on the same set of principals: to modernize our rolling stock, improve our grades and roadbeds, develop industries and engage in modest expansion of our lines.

In this, 1852 was no different. Gone were the hectic years of begging and pleading for loans to drive rails across the wilderness; we operated entirely from our profits. I did not however propose to repay our debts just yet, as we were easily meeting the interest payments and stock dividends. Instead I re-invested those profits in the Great Southern, which was the most solid and secure investment I had knowledge of.

I have spoken earlier of our re-organization of the company and its divisions. In short we established three departments for the railroad. The Atlantic controlled all track from Richmond to Savannah and west to Augusta, Georgia. The Central had the middle section, west of Augusta through Montgomery. As we later built lines north from Atlanta to Louisville, Kentucky, those became a part of the Central Department. Third, and largest in terms of overall traffic, was the Mississippi Department. Mobile, New Orleans and all operations north to Columbus, Kentucky were given to this western-most division. At first, operations to Nashville in Tennessee were given to the Mississippi Department; later, as rails were laid to Atlanta, this was transferred to the Central.

Our industrial operations were similarly grouped, each of three departments reporting to an Industry Department manager who ranked with each of the railroad department managers. At the time it was implemented, this hierarchy was criticized as being top-heavy, with too many divisions and layers of managers. Later, as the company continued to expand, we found no need to re-invent or reapportion.

Arthur McComber had reluctantly accepted my offer of promotion and was now Industrial Division manager for the Mississippi region, retaining some degree of control therefore over his beloved Providence Locomotive Works. It was in 1851 that he had called me down to the Works to see an experimental unit put together by some bright young engineers.

I was eager to go; as the years went by I found that operating a railroad was more time-consuming than building one, yet not as pleasurable. It must have been springtime, for I remember the vivid green of every tree and of each blade of grass. I dispensed with a carriage, for it was a short walk and a fine day. I was careful of my steps, for Caroline was given to fuss if I went about with muddy shoes. Passing around the side of the machine works sheds, I came to a spur track that carried a Baldwin-type 0-6-0, tender and a couple of freight cars. A group of men were gathered around the engine, but they opened up readily enough to let me pass. McComber was incongruous at the engineer's position, dressed in his dark suit. I had to smile when I thought of what both our wives would have to say, but hoisted myself into the cab anyway.

As much as the expense distressed our company's Board, McComber and I insisted on maintaining an active program of experimentation. The properties of steam were not well known at that time - there was even a violent argument in the Navy as to whether steam expanded as a gas, or as something different. There was also little agreement among railroad men on the proper number and size of driving wheels, or the size of fire grate and boiler needed for a given size and number of cylinders, not to mention the raging debate over which settings of the cutoff valve were most efficient. So much of our overhead was literally consumed as fuel and water that increased efficiency was eagerly sought, as were greater pulling power and higher speeds. I knew that McComber had been experimenting with increased draft and higher pressure boilers, and thought he might have something of the sort to show me. I was only partially correct.

"The freight cars are loaded with equipment for the new tool and die in Nashville," McComber said once greetings had been exchanged and introductions made. "The load is heavy, but would average to about four normal cars." With no further explanation he whistled for a clear track, sending men scattering, nodded to the brakeman, who signaled back, and began to work the control levers. Smoothly the engine leaned into the load, acceleration gently but noticeably pressing us back. Our speed quickly mounted, much more quickly than I had thought a laden train could achieve, but we leveled out no faster than our unmodified locomotives. All too soon we arrived at a junction, where there were some sidings and switches. McComber handed off the controls to an engineer, and while the train was being switched about we studied the locomotive from beside the tracks."Nelson improved the injector ports. And Reynolds modified the cutoff. It's a bit more complicated than what we use now but it gives much more power, especially from a rest. The fire grate's been remade - that was McAleer's work. The sum of this is we can generate more steam, and use that steam when we need it. She's not good for long distance steaming at high consumption because we'd need a bigger boiler, but our acceleration is much improved so we get up to speed faster, power up hills better, and increase our average speed over a run."

I of course wanted to know what it would cost to implement throughout our fleet, and McComber's initial figures were attractively low. I gave my approval on the spot, and never have I regretted it. Let other lines boast of the tonnage their machines could haul, or the immense drivers and flying speed of their locomotives. We concentrated on getting the consist rapidly up to speed and maintaining it there, and so set many records for fastest time without making necessarily the fastest absolute speed.

I had wrung another appropriation from the Board for mineral surveys, and this one too returned a favorable result on properties in central Alabama, which we quickly bought up and began to develop. The vast iron deposits of Tennessee we build a tool and die works in Nashville to exploit, and finally replaced the last of the Norris locomotives with Baldwin types. The Norrises were not old in absolute terms, most being in service six years or less, and so were moved to switching work in yards, or used as emergency motive power.

Our only new track was run from Nashville north to Bowling Green, Kentucky, completed in September. Our hopes of pushing on to Louisville were dashed when a terrible wreck occurred in November, whose legal fees, damage claims and repairs totaled $500,000. The proximate cause of the accident was a train of another railroad that was using our track but paying insufficient attention to other traffic, but the track was ours and we bore the brunt of the blame. This also caused our fourth-quarter dividend to drop from 50 to 33 cents, but as in general the economy was strong and improving, these were only temporary setbacks.

The Great Southern continued to finance mineral surveys through 1853 and 54, relying heavily on the talents of Joseph Bolton & Co of Nashville. Experienced in survey, title, abstract, claim and assay work, this company demanded a top price but delivered valuable advice on the quality and quantity of various minerals. Their paperwork was impeccable; we were frequently sued over mineral rights but never lost a case where Bolton had prepared the title.

As our locomotives seemed to be growing in size and power with no limit readily in sight, it was becoming clear that we would not be able to rely much longer upon wood for fuel. For a given size of firebox and grate, the limiting factor for the production of steam is the heat of the fuel, which also assists in the production of greater pressure and power. While abundant, wood was not always available where needed, and the varieties of trees in the South tended toward soft woods like pine rather than harder oak and hickory. This meant the hard wood had to be reserved for ties and lumber, and wet, resinous soft woods made notoriously bad fuel. They produced little heat for the quantity consumed, were prone to pop and crack explosively (which could fling logs entirely off the grate), emitted embers and thick ash onto passengers and coaches, and gummed the firebox unless it was regularly cleaned.

Of the available fuels, coal held great promise and was already extensively used in Northern railroads and on steamships of the oceans and rivers. The only obstacle was to find a large supply within economical distance, and this, partly due to the work of J Bolton & Co, was accomplished when some coal deposits were acquired in Alabama. These were developed to a greater degree in later years but never did supply all our needs for locomotives and industry, necessitating some reliance on wood throughout this period despite the drawbacks entailed.

The economy settled into a strong boom in 1853, enabling us to complete the section from Bowling Green to Louisville, Kentucky and open service through from Nashville. In 1854 we carried a line south from Nashville to Decatur and Huntsville in Alabama, on the Tennessee River. Later in the year we completed the long-awaited leg from Montgomery to Atlanta, making possible a nearly direct route from New Orleans to Richmond.

Our passenger traffic had continued to flourish and freight volume was also increasing. To handle these larger amounts, we set up fast trains solely for passenger and mail traffic. At first these 'specials' were reserved for the eastern seaboard routes: Richmond-Raleigh-Columbia-Charleston, and Charleston-Atlanta and Savannah-Atlanta. Another innovation was our inclusion of a prototypical 'diner' car, serving a cold collation in the front section for luncheon and sporting a gentleman's small bar and smoking room at the rear.

Because of our modest expenditures in 1853, the Great Southern carried over two millions of dollars in liquid cash into 1854, and I was determined to put it to use. Various scheme for paying off our bonds were rejected, as were plans to expand across the Mississippi or into Ohio. In any event, the vast sums expended on fruitless prospecting and on legal fees, settlements and damages thoroughly eroded this sum. Legal trouble continued to dog the railroad as we fended off a pack of groundless suits while coping with some very real tragedies. One such was the infamous derailment in North Carolina in March of 1853, when a spring flood washed out a section of track and a 'special' fast express was wrecked. Of particular note was the settlement of 1854 involving claims that we had built upon land with improper claim and title; despite the baseless nature of the charge a resolution cost us a million of dollars in all.

Political tensions continued to mount; another crisis was averted by the Kansas-Nebraska acts, but no-one believed that any substantive issue had been settled. In the process the South was further embittered, the careers of Senator Douglas and the President nearly wrecked, and the Northern states roused to a fury as the awful events in Kansas - 'Bleeding Kansas' - began to unfold. Despite the scornful deprecation of my Southern friends, I became convinced that some awful calamity - perhaps even war - was inevitably coming. I made efforts to convince my wife that we should take our fortune and move away, but she would not hear of leaving her beloved South, and so I resolved to keep my marriage at all hazard. If I was bound to Caroline and she to the South, then I must exert myself for my adopted homeland.

With this resolve taken, I devoted some weeks to a consideration of what should be done. My personal fortune was reasonably liquid though invested heavily in Great Southern stock, leaving me relatively free of personal financial concerns. Our company was not completely independent in providing its own necessities though nearly so, and we were making great strides in the promotion of Southern industry and manufactures. A quick inventory, however, assured me that the Southern states were deficient in two items: arms, and ammunition. There was a small armory and cannon foundry in Richmond, but its output was very small. The musket works at Harpers Ferry could not be counted upon, located as they were within scant miles of Maryland and Pennsylvania. The largest gunpowder works in the country was DuPont's in Delaware, a slave-holding state but whose people had no special sympathy for the South.

Therefore I cast about for a suitable location for an armory, and found one under my very nose, so to speak, in the mill town of Columbus, Georgia. Perched atop a high bluff on the east bank of the Chattahoochee River, that city was already home to vast textile plants driven by waterpower. One of these, the Eagle Factory, was the largest single factory in the South. And where there are mills there must of necessity be smithies and machine shops, which our railroad had found most convenient. Located on the river bluff not a stone's throw from the door of our Columbus station was a failing gun factory. Its designs were novel but expensive and insufficiently reliable, and its marketing efforts feeble at best, and so it was much in arrears on its payments and in danger of foreclosure. Alerted by the station manager in Columbus of the opportunity, I traveled immediately to that place and made the owners a reasonable offer, which they refused. On hearing that the Great Southern had an interest, however, the bank that held the notes brought such pressure for payment that the owners were reluctantly forced to sell.

Having come into ownership of the equipment, which I desired greatly, and the inventory, which was essentially superfluous, I immediately set about the fulfillment of our most pressing need, that of customers. In those days the great prize was to secure a military contract, yet the small arsenals at Harpers Ferry and Springfield, Massachusetts sufficed to fill the needs of the federal and state forces. I did not think we could compete in that market - and I was correct - but I was dismayed at the few other available buyers. Just when I was ready to concede a mistake and look for an alternative, my task was suddenly eased by the outbreak of the Crimean War. Overnight, half of Europe was scrambling for additional rifled muskets, and our surplus inventory was snapped up regardless of its dubious reputation.

It was clear to me that, in order to be profitable, we needed a design that was rugged, easy of maintenance and inexpensive to manufacture. For a rifled musket, this was not an easy design specification to meet, nor were we able to winnow out a promising design from the horde of inventors who descended upon us. Speed being of the essence, we paid the necessary fees and began turning out copies of the 1853 model 3-band Enfield as rapidly as possible. Despite a slow start and some errors in training up our work force, the venture was soon modestly profitable. With the end of the Crimean War, we expanded our sales into the Caribbean and South American states and retained a modest profitability. I confess, I did engage in some deception of the company officers in that we produced more rifles than we sold. This excess was warehoused under various excuses; for contracts supposedly not paid, for promotional use, in anticipation of higher sale price at a future time, or simply by listing perfect rifles as manufacturing errors. In this manner we built up a stock of thousands of unsold rifles.

One area in which we had no success whatsoever was in the manufacture of small arms, the lack of which was sorely felt by our forces during the War.

The early part of this decade had seen our revenues grow steadily from five millions to nearly nine millions of dollars, and profits from two and a half to five and a half millions. For a variety of reasons, including the losses incurred by our new arms manufactory, the revenue and profits of 1854 represented a high water mark we were not to attain again until the great War inflated the currency and drove up prices.

Copyright © 2006 - E. Porter Hopson - All Rights Reserved.